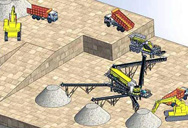

agro broyage prix de la machine en Inde POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à contact us pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- machines pour linstalation de lusine de transformation de lananas

- la machine allemagne de mine d'or de l'Allemagne à vendre

- fer fabricants minerai de concassage mexique

- Mobile Crushers prefere

- peugeot boxer benne occasion en tunisie

- jenis matériau pisau concasseur

- moulin broyeur de fourrage

- le transporteur 4 date de sortie

- usine de marbre espagne

- http dot concasseur Web de p 110

- type de broyeur a marteaux drotsky utilisé en namibie

- convertisseur automatique industriel

- comment séparer l&39;or fin du sable

- masse volumique de la pierreéquipement de Concassage

- debourser fabricants de concasseurs

a vendre Philippines equipements roche carriere

Les concasseurs - CONMACH

Concasseurs à Arbre Vertical (VSI) Les concasseurs VSI, qui brisent le matériau grâce à un rotor tournant à grande vitesse, conviennent particulièrement aux processus de concassage fin et à la production de sable. Domaines d’Utilisation des Concasseurs. Les

Read More

Fabricant Producteur concasseurs - Europages

276 Entreprises 156 Produits. Recommandation produits. Concasseur À Mâchoires (umk) Turquie. Concasseur à percussion Gasparin K90 - K90R. France. CONCASSEUR

Read More

Concasseur, Unité de concassage - Tous les

Trouvez facilement votre concasseur parmi les 1 017 références des plus grandes marques (Jwell, Retsch, Fritsch GmbH, ...) sur DirectIndustry, le spécialiste de l’industrie pour vos achats professionnels.

Read More

La nouvelle génération de concasseurs à mâchoires Finlay

2024年2月28日 Finlay®, l'un des principaux fabricants mondiaux d'équipements mobiles de concassage, de criblage et de transport, est fier d'annoncer l'introduction de deux

Read More

CONCASSEUR Roc Impact et Matériel pour mines

ROC IMPACT dispose d’une large gamme de concasseurs robustes et adaptées aux mines et carrières : Concasseur à mâchoires, Broyeur à Cône, Broyeur à percussion et Groupe mobile de concassage.

Read More

Meilleur concasseur et crible, fabricant de concasseur Sanyyo

Établi depuis 1986 avec RD et produisant des matériaux résistants à l'usure, Shanghai Leiyou Complete Machinery Co., Ltd., est maintenant devenue une entreprise par

Read More

Concasseur à percussion, Unité de concassage à percussion

Trouvez facilement votre concasseur à percussion parmi les 392 références des plus grandes marques (Jwell, Liming, Fabo, ...) sur DirectIndustry, le spécialiste de l’industrie

Read More

Concasseur pour matériau de construction - Tous les fabricants

Trouvez facilement votre concasseur pour matériau de construction parmi les 153 références des plus grandes marques (Jwell, Liming, Metso, ...) sur DirectIndustry, le

Read More

Concatec : Au service des mines et carrières

2012年1月20日 BIENVENUE CHEZ . Notre présence au Maroc depuis plus de 20 ans dans le domaine des mines et carrières nous offre une parfaite maîtrise du marché marocain grâce à l’expérience de nos

Read More

Bien choisir un concasseur - Guides d'achat

3 天之前 Un concasseur est une machine de broyage qui utilise l’énergie mécanique pour briser des blocs de pierre, de béton, ou d’autres matériaux de construction, en blocs plus petits de granulométrie déterminée. Ils

Read More

Concasseur haute capacité, Unité de concassage haute

Fabricants. A; Aceretech (20) AYMAS MAKINA SAN. ve TIC. A.S. (2) B; Boratas Machinery (14) C; Changshu Shouyu Machinery Co.,Ltd (1) ... Les concasseurs de pierres que nous produisons pour de nombreux pays du monde disposent des meilleurs équipements et du meilleur design. Pierre fixe à vendre, nous sommes toujours le partenaire de solution de ...

Read More

Concasseur secondaire, Unité de concassage secondaire

Fabricants. B; Binder+Co AG (4) Boratas Machinery (12) C; CONSTMACH Concrete Plants Crushers (7) E; EDGE Innovate (1) Eriez Magnetics Europe Limited (1) F; ... Des solutions complètes de concasseurs à mâchoires, de concasseurs à cônes, de concasseurs à impact à axe vertical et de concasseurs ...

Read More

Concasseur à mâchoire, Unité de concassage à mâchoire

Capacité: 50 t/h - 1 000 t/h Puissance moteur: 250, 132, 160, 75 kW Hauteur de l'ouverture: 650, 850, 1 000, 1 200 mm... primaire. Les concasseurs à mâchoires, en appliquant une pression élevée sur le matériel alimenté, cassent les pierres.Cette pression mécanique assure le mouvement elliptique de la mâchoire...

Read More

Concasseur à percussion, Unité de concassage à percussion

stationnaire primaire. Capacité: 200 t/h - 600 t/h. Puissance moteur: 250 kW - 500 kW. Les Concasseurs à percussion primaire CONSTMACH sont d'excellentes solutions pour le broyage de matériaux mous et durs moyens avec une capacité de production élevée et des produits de forme cubique.

Read More

Concasseur à percussion, Unité de concassage à percussion

Fabricants. A; ATM Recyclingsystems GmbH (2) AYMAS MAKINA SAN. ve TIC. A.S. (1) B; ... à leur taux de réduction élevé et à la forme cubique parfaite de leurs produits finaux, les concasseurs à percussion ... Les concasseurs à percussion Maxtec Lion sont conçus pour le broyage de granit et de calcaire naturel de taille douce à moyenne, ...

Read More

TOP 5 des fabricants de concasseurs à mâchoires en Chine

2019年4月22日 MGS Casting se spécialise dans la fabrication de pièces de concasseur à mâchoires pour tous les clients. Certains de nos clients sont des marques de concasseurs locales en Chine. Nos pièces d'usure pour concasseurs à mâchoires aident leurs concasseurs à mâchoires à obtenir une durée de vie plus longue. En ce moment, nous

Read More

TOP 5 des fabricants de revêtements de concasseurs à

2021年5月26日 L'auteur a travaillé dans une fonderie de moulage et a aidé la fonderie à exporter des pièces d'usure en fonte pendant 10 ans. Sur la base de mon expérience, je souhaite vous montrer « les 5 meilleurs fabricants de revêtements de concasseurs à mâchoires en Chine ». Table des matières cacher. 1 Usine de coulée de précision 1.Wuyi ...

Read More

Concasseur à cône, Unité de concassage à cône - Tous les fabricants ...

Ceux-ci se coincent à nouveau et sont écrasés une nouvelle fois, et ainsi de suite jusqu'à obtention de la taille de blocs recherchée. Applications. Les concasseurs à cône sont utilisés pour du concassage secondaire ou tertiaire sur des matériaux mi-durs à durs, et sont très présents dans l'industrie minière et les carrières.

Read More

Concasseur à percussion, Unité de concassage à percussion

Capacité: 200 t/h - 600 t/h Puissance moteur: 200, 250 kW Hauteur de l'ouverture: 920, 1 580 mm. Les concasseurs primaire à percussion de la série UĞURMAK CDK ont une conception qui permet avec un rotor, deux systèmes pendulaires et des plaques d'usure de fonctionner en harmonie. Grâce à cette compatibilité, ...

Read More

Concasseur à mâchoire, Unité de concassage à mâchoire

unité de concassage à mâchoire CJC-60. stationnaire primaire haute capacité. Capacité: 100 t/h - 1 t/h. Puissance moteur: 300 kW - 200 kW. Poids: min 6000.0 kg. En tant que premier fabricant de concasseurs à mâchoires en Turquie, nous vous offrons un service de qualité avec un concasseur à mâchoires.

Read More

Fabricants de concasseurs en Chine - Concasseur à bon prix

6 天之前 ZHONGXIANG est l'un des fabricants de concasseurs les plus professionnels en Chine, caractérisé par un bon service et des prix compétitifs. Nous vous invitons chaleureusement à acheter un concasseur de haute qualité à vendre ici dans notre usine. info@cnzxme +8613849073582. Langue.

Read More

Fabricant Producteur concasseurs - Europages

L'entreprise GELEN MAKINA A.S, est un Fabricant/ Producteur, qui travaille dans le secteur Mines et carrières - machines et matériel. Elle est également présente dans les secteurs machines pour le broyage des agrégats, concasseurs, Concasseurs à percussion, et installations de lavage inertes de carriere. Elle est basée à Ankara, Turquie.

Read More

Concasseur mobile, Unité de concassage mobile

Contacter. Capacité: 80 t/h. Puissance moteur: 77 kW. Hauteur de l'ouverture: 640 mm. Le RM 60 est le concasseur mobile par ampli-roll de RM et le choix idéal: que ce soit pour exploiter des niches ou concasser

Read More

debourser fabricants de concasseurs

Broyeur pour ciment - Tous les fabricants industriels. Vitesse de rotation: 70 rpm Longueur de la machine: 120 cm. Avec un diamètre de cellule de broyage de 33 cm et une durée de broyage maximale de 3 heures, le Ball Bill est . Consulter un spécialiste

Read More

Crible pour l'alimentation de concasseurs - Tous les fabricants

Trouvez facilement votre crible pour l'alimentation de concasseurs parmi les 15 références des plus grandes marques (Fabo, Metso, Terex, ...) sur DirectIndustry, le spécialiste de l’industrie pour vos achats professionnels.

Read More

Concasseur pour le tertiaire, Unité de concassage pour le tertiaire ...

Fabricants. B; Binder+Co AG (2) Boratas Machinery (11) C; CONSTMACH Concrete Plants Crushers (2) F; Fabo Crushing Screening Concrete Plants (16) ... Des solutions complètes de concasseurs à mâchoires, de concasseurs à cônes, de concasseurs à impact à axe vertical et de concasseurs ...

Read More

Concasseur pour production de sable - Tous les fabricants

Fabricants. B; BHS-Sonthofen : Building Materials Machinery / Rec (1) C; CIMMA (1) CONSTMACH Concrete Plants Crushers ... de concasseurs à cônes, de concasseurs à impact à axe vertical et de concasseurs... Ajouter au comparateur Retirer du comparateur. concasseur à cône MCH Line. stationnaire pour production de sable compact.

Read More

Concasseur pour les matières minérales - Tous les fabricants

Fabricants. B; Boratas Machinery (10) C; CIMMA (1) CM Srl (3) CONSTMACH Concrete Plants Crushers (1) F; Fabo Crushing Screening Concrete Plants (4) ... Des solutions complètes de concasseurs à mâchoires, de concasseurs à cônes, de concasseurs à impact à axe vertical et de concasseurs ...

Read More

Concasseur à cône, Unité de concassage à cône - Tous les fabricants ...

Trouvez facilement votre concasseur à cône parmi les 163 références des plus grandes marques (SIEBTECHNIK, Meyn Foodprocessing Technology, ...) sur DirectIndustry, le spécialiste de l’industrie pour vos achats professionnels. Page 2

Read More

Concasseur fin, Groupe de concassage et de criblage fin

Fabricants. A; Aceretech (1) AYMAS MAKINA SAN. ve TIC. A.S. (1) B; bccm (1) Boratas Machinery (6) C; CIMMA (1) CONSTMACH Concrete Plants Crushers (3) F; ... Des solutions complètes de concasseurs à mâchoires, de concasseurs à cônes, de concasseurs à impact à axe vertical et de concasseurs ...

Read More